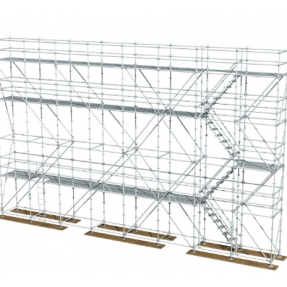

Ringlock Scaffolding

Ring lock scaffolding (also known as disc-type scaffolding or disc-type steel pipe scaffolding) is anew, efficient load-bearing support and constnuction tool. With its stable structure, easyinstallation, and high safety factor, it is widely used in construction projects, bridge constructionand large equipment installation. it has gradually replaced traditional coupler-type scaffoldingand become one ofthe mainstream scaffolding types in modern engineering construction.

Specifications for selection and design: Scaffolding upright spacing, crossbar pitch, and diagonalbar density must be calculated based on project loads (construction load, deadweight, wind loadetc.). Excessive loads are strictly prohibited. Complex scenarios (such as large spans and ultra-high formwork)require a specialized construction plan from a professional engineer.

Pre-installation inspection: Before use, inspect the appearance of components (for signs ofbending, cracks, or excessive rust), ensure the pins are flexible, and ensure the disc welds aresecure. Unqualified components must not be used. Ensure the construction surface is flat andsolid. Adjustable bases must be padded with pads (such as steel plates or wooden planks) toprevent settlement. Safety measures: Safety nets must be installed outside the scaffolding asrequired. The working level scaffolding boards must be fully laid and securely fixed (no gapsallowed), Workers must wear safety helmets and safety belts. Stacking heaw materials on thescaffolding is strictly prohibited.

Regular Inspection and Maintenance: During use, regularly check for loose joint pins, bent poles.and baseplate settlement. Any problems should be corrected promptly. After completion,components must be sorted, cleaned, rusted, and repainted (if the zinc coating is damaged)Store in a dry, well-ventilated area to protect from rain and rust.

Vertical Pole: The vertical load-bearing structure of thescaffolding.A circular node is welded to the pole at regularintervals (usually 500mm, 750mm, or 1000mm). The disk haseight evenly spaced connection holes for connecting to thehorizontal and diagonal poles. it can be extended using\"vertical pole connection sleeves\" to meet project heightrequirements.

Horizontal Pole: The horizontal load-bearing and stabilizingmember. \"Horizontal Pole Connectors\" with latches arewelded at both ends. These connectors are inserted into theconnection holes of the vertical pole disks and locked withlatches to form a horizontal frame, carrying constructionloads and transferring them to the vertical poles.

Diagonal Poles: Key components that enhance thescaffold\'s overall resistance to lateral movement andoverturning.These components consist of verticaldiagonals (installed along the height of the uprights) andhorizontal diagonals (installed along the length of thecrossbars). Both ends feature latch joints, which, whenconnected to the discs, form a stable triangular strctureenhancing the scaffold\'s overall rigidity.

Disc Nodes:Core connectors, stamped from Q355B-gradesteel, are welded to the uprights. Eight connection holesallow for flexible connection of the crossbars and diagonalsin different directions, ensuring uniform force distribution atthe nodes and avoiding the \"single-point force\" drawback oftraditional fasteners.

Auxiliary components: These include adjustable bases (foradjusting upright height and adapting to uneven surfaces)adjustable top supports (for supporting formwork or upperloads and fine-tuning height), scaffolding boards (laid onthe crossbars to provide a construction working surface).and safety net supports, enhancing the scaffold\'sfunctionality and safety

SMPRE™

SMPRE™

799384842

799384842 +86-17606489157

+86-17606489157 info@simenprecast.com

info@simenprecast.com Simen

Simen