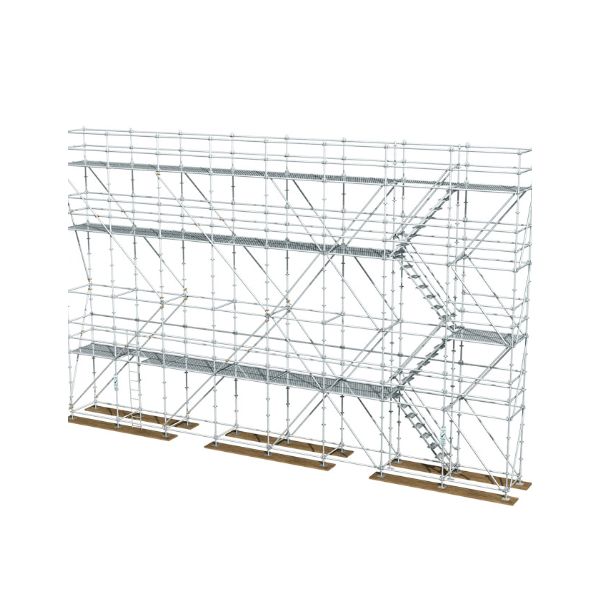

Ringlock Scaffolding

● Robust Construction:Manufactured from high-strength Q235/Q345B steel with hot-dip galvanisation, delivering outstanding corrosion resistance for enduring performance across diverse climates from Southeast Asia to Africa and the Middle East.

● Innovative Ring-Lock Design: Quick-locking rose discs enable rapid assembly and disassembly without loose fittings, reducing labour time by up to 50% compared to traditional systems.

● Enhanced Safety and Stability: Fitted with diagonal braces and crossbar locks to guarantee maximum load capacity (single-pole ultimate load of 20 tonnes [60×3.2] at 1.5m spacing, 17 tonnes for 48×3.2) and worker prote protection.

● Versatile Configuration: Customisable height, width, and accessories (including planks, stairs, and toe boards) to accommodate any project scale—from urban developments to remote Belt and Road infrastructure sites.

- Description

- Advantage

- Application

- Accessories

Ring lock scaffolding (also known as disc-type scaffolding or disc-type steel pipe scaffolding) is anew, efficient load-bearing support and constnuction tool. With its stable structure, easyinstallation, and high safety factor, it is widely used in construction projects, bridge constructionand large equipment installation. it has gradually replaced traditional coupler-type scaffoldingand become one ofthe mainstream scaffolding types in modern engineering construction.

Specifications for selection and design: Scaffolding upright spacing, crossbar pitch, and diagonalbar density must be calculated based on project loads (construction load, deadweight, wind loadetc.). Excessive loads are strictly prohibited. Complex scenarios (such as large spans and ultra-high formwork)require a specialized construction plan from a professional engineer.

SMPRE™

SMPRE™

799384842

799384842 +86-17606489157

+86-17606489157 info@simenprecast.com

info@simenprecast.com Simen

Simen