Enhanced Galvanized Cast-In Plates Debut to Elevate Precast Concrete Construction

Views: 46 Update date: Jan 22,2026

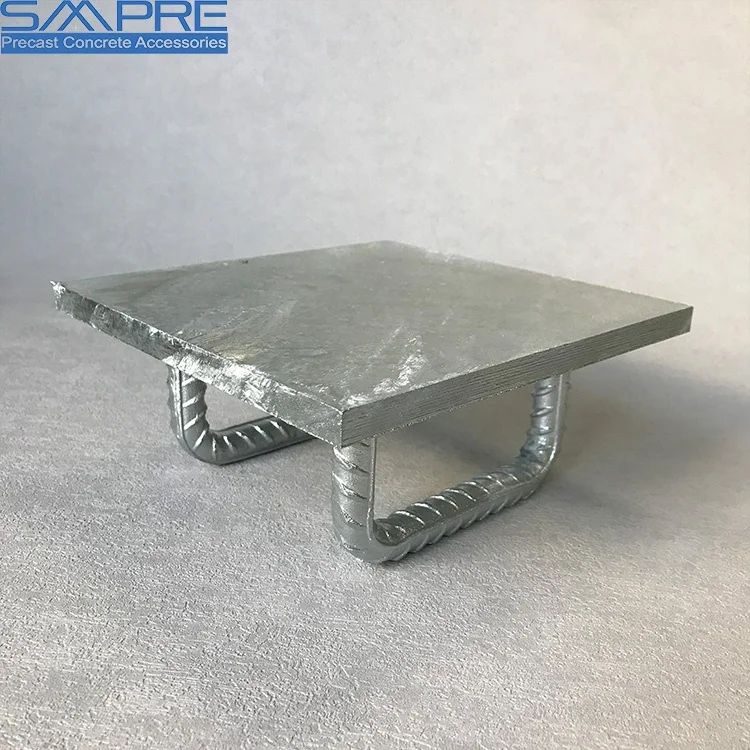

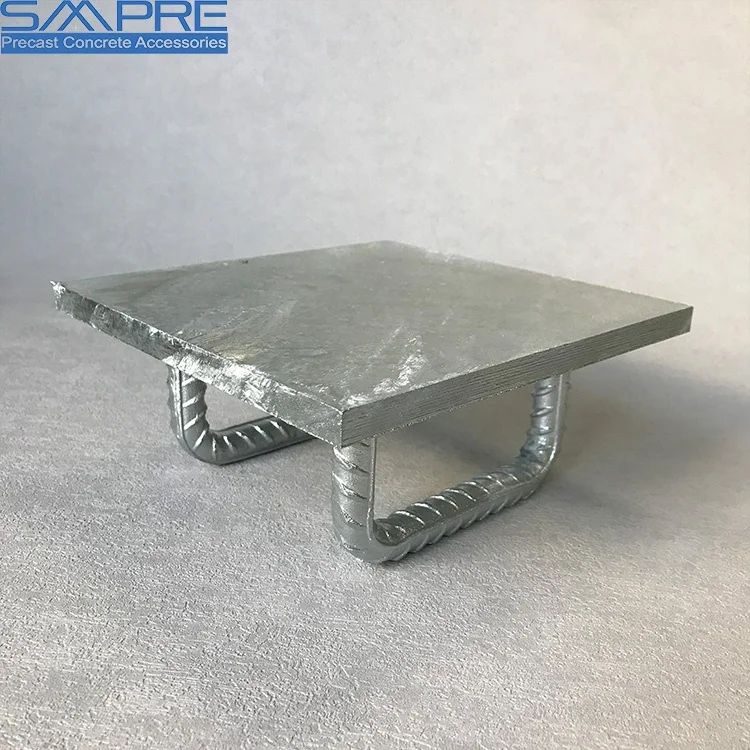

SMPRE, a professional provider of precast concrete accessories with mature production experience, officially announced the launch of its upgraded galvanized cast-in plate series on Monday. This product upgrade sets a new benchmark for reliable and efficient precast concrete connections, tailored to the practical needs of modern construction projects. Made of high-quality low-alloy steel—chosen for its excellent tensile strength and ductility—the new cast-in plates adopt advanced precision manufacturing processes in our factory, ensuring stable performance and long service life in residential, industrial and infrastructure projects.

The core advantage of this product lies in its upgraded hot-dip galvanization process, which is more reliable than conventional coating methods. Our factory implements strictly controlled hot-dip galvanizing: plates are fully submerged in 450°C molten zinc, forming a thick, uniform zinc-iron alloy coating that adheres firmly to the steel surface. With a minimum thickness of 85 microns (exceeding ASTM A123 standards), the coating effectively resists corrosion, making the product suitable for both indoor and harsh outdoor environments such as coastal, humid and industrial areas. Unlike electroplated products, it has self-healing properties—minor scratches trigger galvanic protection to prevent rust, extending service life to over 50 years in moderate environments and 30+ years in severe conditions, reducing subsequent maintenance costs for customers.

To enhance connection reliability, our factory optimized the anchor design with welded deformed bar anchors. These precision-fabricated anchors have ribbed surfaces that strengthen interlocking with concrete, enabling secure load transfer and withstanding high tensile and shear forces—third-party tests show 20% higher load-bearing capacity than standard products. We use robotic welding equipment in production, eliminating human error and ensuring consistent weld quality, which is crucial for high-load scenarios like bridge piers and beam-column connections. Additionally, the flat, smooth plate surface minimizes concrete voids during casting, further improving structural stability.

Designed for versatility and on-site efficiency, the new cast-in plates fit various precast construction needs, including connecting load-bearing walls, columns, beams, facade panels and staircases. With pre-drilled holes and standardized dimensions, they can be easily integrated into precast forms without custom modifications. A key benefit for contractors is no on-site welding—our factory prefabricates the anchor-welded plates, reducing on-site labor time by up to 35%, cutting equipment costs and lowering fire and quality risks, which aligns with practical construction efficiency demands.

The combination of performance, durability and convenience makes this product a practical choice for modern precast projects. Our factory spent two years optimizing the product through repeated tests and feedback from cooperative contractors and engineers, focusing on solving core problems like corrosion, unstable load-bearing and on-site inefficiency, while complying with ACI 318, EN 1090 and ISO 1461 standards. The prefabricated design also reduces material waste, in line with practical energy-saving requirements of construction projects.

An SMPRE spokesperson said, "We are committed to providing practical accessories for the construction industry. This upgrade reflects our customer-centric approach—we listened to on-site pain points from our clients, such as coastal corrosion and tight deadlines, and tailored a solution that delivers real value. Whether for large infrastructure or small residential projects, our products help contractors complete projects on time, within budget and with reliable quality."

The new galvanized cast-in plates are now available globally. Our factory offers customizable sizes (100x100mm to 500x500mm), anchor lengths and configurations to meet project-specific needs. We also provide technical support including on-site installation guidance, load calculation and custom solutions for complex projects. For specifications and orders, contact our sales team or visit our official website.

With years of experience in precast concrete accessories, SMPRE has a solid reputation for reliable products. This launch strengthens our market position, catering to the growing demand for high-quality precast connections. Our factory will continue to focus on practical product optimization to support construction projects with more reliable solutions.

Prev: Qingdao Simen Precast Co.,Ltd Commits to On-Time Delivery, Quality & After-Sales Service

Next: Has SMPRE unveiled Long Wavy Tail Threaded Anchor for high-strength precast concrete connections?

SMPRE, a professional provider of precast concrete accessories with mature production experience, officially announced the launch of its upgraded galvanized cast-in plate series on Monday. This product upgrade sets a new benchmark for reliable and efficient precast concrete connections, tailored to the practical needs of modern construction projects. Made of high-quality low-alloy steel—chosen for its excellent tensile strength and ductility—the new cast-in plates adopt advanced precision manufacturing processes in our factory, ensuring stable performance and long service life in residential, industrial and infrastructure projects.

The core advantage of this product lies in its upgraded hot-dip galvanization process, which is more reliable than conventional coating methods. Our factory implements strictly controlled hot-dip galvanizing: plates are fully submerged in 450°C molten zinc, forming a thick, uniform zinc-iron alloy coating that adheres firmly to the steel surface. With a minimum thickness of 85 microns (exceeding ASTM A123 standards), the coating effectively resists corrosion, making the product suitable for both indoor and harsh outdoor environments such as coastal, humid and industrial areas. Unlike electroplated products, it has self-healing properties—minor scratches trigger galvanic protection to prevent rust, extending service life to over 50 years in moderate environments and 30+ years in severe conditions, reducing subsequent maintenance costs for customers.

To enhance connection reliability, our factory optimized the anchor design with welded deformed bar anchors. These precision-fabricated anchors have ribbed surfaces that strengthen interlocking with concrete, enabling secure load transfer and withstanding high tensile and shear forces—third-party tests show 20% higher load-bearing capacity than standard products. We use robotic welding equipment in production, eliminating human error and ensuring consistent weld quality, which is crucial for high-load scenarios like bridge piers and beam-column connections. Additionally, the flat, smooth plate surface minimizes concrete voids during casting, further improving structural stability.

Designed for versatility and on-site efficiency, the new cast-in plates fit various precast construction needs, including connecting load-bearing walls, columns, beams, facade panels and staircases. With pre-drilled holes and standardized dimensions, they can be easily integrated into precast forms without custom modifications. A key benefit for contractors is no on-site welding—our factory prefabricates the anchor-welded plates, reducing on-site labor time by up to 35%, cutting equipment costs and lowering fire and quality risks, which aligns with practical construction efficiency demands.

The combination of performance, durability and convenience makes this product a practical choice for modern precast projects. Our factory spent two years optimizing the product through repeated tests and feedback from cooperative contractors and engineers, focusing on solving core problems like corrosion, unstable load-bearing and on-site inefficiency, while complying with ACI 318, EN 1090 and ISO 1461 standards. The prefabricated design also reduces material waste, in line with practical energy-saving requirements of construction projects.

An SMPRE spokesperson said, "We are committed to providing practical accessories for the construction industry. This upgrade reflects our customer-centric approach—we listened to on-site pain points from our clients, such as coastal corrosion and tight deadlines, and tailored a solution that delivers real value. Whether for large infrastructure or small residential projects, our products help contractors complete projects on time, within budget and with reliable quality."

The new galvanized cast-in plates are now available globally. Our factory offers customizable sizes (100x100mm to 500x500mm), anchor lengths and configurations to meet project-specific needs. We also provide technical support including on-site installation guidance, load calculation and custom solutions for complex projects. For specifications and orders, contact our sales team or visit our official website.

With years of experience in precast concrete accessories, SMPRE has a solid reputation for reliable products. This launch strengthens our market position, catering to the growing demand for high-quality precast connections. Our factory will continue to focus on practical product optimization to support construction projects with more reliable solutions.

SMPRE™

SMPRE™

799384842

799384842 +86-17606489157

+86-17606489157 info@simenprecast.com

info@simenprecast.com Simen

Simen